A Step-by-Step Guide to Piping Network Calculation

Understanding Piping Networks

Piping networks play a crucial role in various industries, facilitating the movement of process and utility fluids to ensure smooth operations. Piping networks are an integral part of oil & gas projects, forming a significant portion of the final plant and cost estimate. The components of a piping network include pipes, fittings, flanges, valves, gaskets, and fasteners. These items come in various sizes, pressure ratings, and metallurgies to meet diverse operational requirements.

Examples in Everyday Life

In everyday life, piping networks are omnipresent but often unnoticed. Water distribution systems in cities rely heavily on extensive piping networks to deliver clean water to homes and businesses. However, the average US water-network pipe is 45 years old, with some cast-iron pipes exceeding a century in age. This aging infrastructure has led to high water-loss rates from leaks in the water distribution network system.

Components of a Piping Network

The primary components of a piping network include pipes, valves, and fittings. Each component plays a distinct role in ensuring the seamless flow of fluids within the network. Pipes act as conduits for fluid transportation while valves control the flow rate and direction. Fittings are used to connect different sections of pipes or change their direction.

The material take-offs for various lines within piping networks can be extensive due to repeated items across multiple sections. This results in long lists during the estimation process. Additionally, more than $234 billion is expected to be invested over the next decade to address aging municipal water and wastewater pipe network infrastructure across the United States.

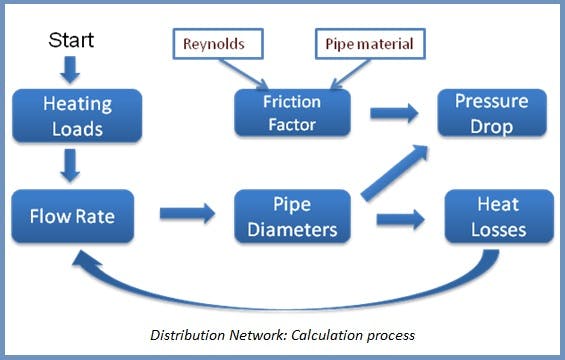

The Basics of Piping Network Calculation

Piping network calculation is a fundamental aspect of engineering and construction projects, essential for ensuring the efficient and safe transportation of fluids. The process involves several key steps to gather necessary data, choose the right formula, and perform accurate calculations.

Step 1: Gathering Necessary Data

Before embarking on any piping network calculation, it's crucial to gather comprehensive data regarding measurements, specifications, and flow rates. This includes obtaining precise measurements of the piping system, such as length, diameter, and material specifications. Understanding flow rates is equally important as it directly impacts the selection of appropriate pipe sizes and components.

In a recent patent titled "Leak test system and method for thermoplastic piping," a novel approach to leak testing thermoplastic piping systems was introduced. The patent describes a system that utilizes an air pump to pressurize the piping system with air while maintaining pressure within prescribed limits using advanced control mechanisms. This innovative method ensures the safety and integrity of the piping network during testing procedures.

Step 2: Choosing the Right Formula

Selecting the right formula is critical in piping network calculation as it directly influences the accuracy of the results. Basic calculation principles based on fluid dynamics and material properties play a significant role in determining the appropriate formulas for specific scenarios. Additionally, software tools can simplify complex calculations by automating repetitive tasks and providing accurate results with minimal manual effort.

An excerpt from an industry expert's insights highlights the time-consuming nature of detailed piping estimates in oil & gas projects. The estimation process often involves hundreds or even thousands of line items, emphasizing the need for efficient calculation methods. Utilizing specialized software tools can significantly streamline this process, allowing estimators to generate precise results in a more time-effective manner.

Step 3: Performing the Calculation

Once all necessary data has been gathered and the appropriate formula selected, it's time to perform the actual piping network calculation. Engineers have two primary options for conducting these calculations: manual methods or utilizing specialized software. While manual calculations provide a deeper understanding of underlying principles, software tools offer speed and efficiency in handling complex networks.

The integration of ultrasonic leak detection devices into piping network testing procedures represents a significant advancement in ensuring system integrity. By leveraging advanced technology, potential leaks within piping systems can be accurately located, contributing to enhanced safety measures during operation.

Estimating Piping Cost

Estimating the cost of a piping network is a critical aspect of project planning and budgeting. Several factors influence the overall cost, including material types and labor expenses. Understanding these elements is essential for accurate cost estimation and effective cost-saving strategies.

Factors Influencing Piping Cost

Material Types

The choice of piping materials significantly impacts the overall project cost. Different materials have varying price points and installation requirements. For instance, the price of pipes ranges from about $0.40 to $10.00 per linear foot, depending on the type of material. Metal pipes generally cost more than plastic ones due to their durability and strength properties. It's widely recommended that homeowners replace galvanized steel and cast iron pipes with either traditional copper or one of the newer plastic options, such as PEX and CPVC, to mitigate corrosion issues.

Labor and Installation

Labor expenses constitute a substantial portion of piping costs. Homeowners should be prepared to allocate approximately $1-2 per linear foot for labor during pipe installation. The installation cost ratios vary for different piping materials, with metal pipes generally incurring higher installation expenses compared to plastic alternatives.

Calculating Piping Cost

Accurately calculating piping costs involves employing basic estimation techniques and implementing practical cost-saving measures.

Basic Cost Estimation Techniques

When estimating piping costs, it's crucial to consider both material expenses and labor costs. Utilizing comparative data for different piping materials can provide valuable insights into their respective price points and installation requirements. This information enables project planners to make informed decisions regarding material selection based on budget constraints without compromising quality.

Tips for Cost-Saving

Implementing effective cost-saving strategies is essential for optimizing piping network expenditures without sacrificing performance or safety standards. One approach involves leveraging innovative piping materials that offer a balance between affordability and longevity, such as modern plastic options like PEX and CPVC. Additionally, collaborating with experienced contractors who specialize in efficient pipe installation techniques can contribute to minimizing labor expenses while ensuring high-quality workmanship.

Case Study: Piping Cost in Westminster

Overview of Piping in Westminster

Westminster, a bustling city with a diverse industrial landscape, faces unique challenges related to its piping network. The local piping infrastructure is subjected to varying environmental conditions and operational demands, necessitating robust systems capable of withstanding these pressures.

Local Piping Challenges

The geographical location of Westminster exposes its piping networks to temperature fluctuations and potential corrosion risks due to environmental factors. Additionally, the city's expanding urban footprint requires continuous expansion and maintenance of the existing piping systems to meet growing demand while ensuring reliable service delivery.

Average Costs and Factors

In Westminster, the average piping cost is influenced by several key factors. Material selection plays a pivotal role in determining overall expenses, with considerations for durability, corrosion resistance, and installation requirements. Labor costs also contribute significantly to the total project expenditure, reflecting the skilled workforce necessary for efficient installation and maintenance.

Lessons Learned

Cost Management Strategies

Effective cost management strategies are essential for optimizing piping cost in Westminster. Implementing proactive maintenance schedules and utilizing durable materials can mitigate long-term expenses associated with frequent repairs or replacements. Furthermore, strategic planning that incorporates life cycle cost analysis enables stakeholders to make informed decisions regarding initial investments versus ongoing operational costs.

Application of Calculation Techniques

The application of accurate calculation techniques is paramount in estimating piping cost within the dynamic environment of Westminster. By leveraging advanced software tools tailored to address specific project requirements, engineers can streamline the estimation process and generate precise cost projections. This approach facilitates informed decision-making by providing comprehensive insights into material selections and labor allocations based on calculated estimations.

Final Thoughts

Recap of Key Points

In conclusion, understanding the intricacies of piping networks and their calculation processes is vital for various industries. The components of a piping network, including pipes, valves, and fittings, form the backbone of fluid transportation systems. Gathering comprehensive data and choosing the right formula are crucial steps in accurately estimating piping costs.

The Importance of Accurate Calculations

Accurate calculations are paramount in ensuring the efficiency and safety of piping networks. From material selection to labor expenses, every aspect contributes to the overall cost estimation. By employing precise calculation techniques and leveraging advanced software tools, engineers can streamline the estimation process and make informed decisions regarding material selections and labor allocations.

Further Resources and Learning

For further exploration into piping network calculations and cost estimation, there are numerous resources available. Industry publications, online forums, and professional associations offer valuable insights into best practices and emerging technologies in the field. Additionally, specialized courses and workshops provide opportunities for continuous learning and skill development in the realm of piping network engineering.

Explore the step-by-step guide to piping network calculation, including cost estimation tips. Learn about piping network, calculation, and cost in Westminster

Know more:https://maps.app.goo.gl/YtNR9rs7ZqCjTduo8.